Product Introduction

The PTO Shaft for Hesston Square Balers 4690 4690S is a highly efficient and reliable component designed to enhance the performance of your agricultural machinery. This PTO shaft is a vital accessory for Hesston Square Balers 4690 and 4690S models, delivering superior power transmission for optimal operation.

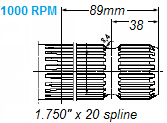

The PTO shaft comes with a new CV (Constant Velocity) feature, without implementing yoke, and has a size 6. The C-to-C length is 48″ (1210 mm), and the tractor end has 6,1-3/8″ splines. This assembly replaces the tractor half PTO driveline and may require cutting to length.

Product Features and Maintenance

The PTO Shaft offers a range of features that contribute to its high performance. The shaft is designed to fit Case-IH and Hesston square balers and comes without an implement yoke. This is a complete PTO driveline assembly that replaces the tractor half PTO driveline.

To keep your PTO Shaft in optimal condition, it is crucial to perform regular maintenance. This includes lubrication at hourly intervals as indicated and regular cleaning of the inner and outer sliding surfaces of the telescopic section of the guard.

Cutting the PTO Shaft to Length

Cutting the PTO shaft to the correct length is essential for effective operation. To do this, remove the safety shield, shorten the inner and outer tubes according to the required length, deburr the edges of the drive tubes, and grease the internal drive tubes before reassembling them with a safety shield.

About Us

We are a leading manufacturer in the agricultural machinery parts industry, specializing in PTO shafts, industrial universal shafts, automobile drive shafts, universal joint coupling shafts, and universal joints. With an annual turnover of 60 million yuan and 9 million US dollars, our products are highly reputable among customers worldwide. We are committed to delivering top-quality products that adhere to our “QDP” principle: Quality first, Quick delivery, and Competitive price.

Other Products

In addition to our PTO shafts, we offer a wide range of agricultural gearboxes for your agricultural machinery needs. Our products are designed to provide reliable and efficient power transmission for various applications.

Q&A

1. Q: How often should I lubricate the PTO Shaft?

A: We recommend lubricating the driveline shaft parts at hourly intervals as indicated.

2. Q: What is the purpose of the new CV (Constant Velocity) feature?

A: The CV feature provides consistent power transmission for optimal operation.

3. Q: How can I ensure the correct length of the PTO shaft?

A: You may need to cut the driveline to the required length, ensuring sufficient overlap of the drive tubes in all working positions.

4. Q: What other products do you offer?

A: We offer a wide range of agricultural machinery parts, including agricultural gearboxes, belts, and chains.

5. Q: How can I purchase your products?

A: You can explore and purchase our products through our website.